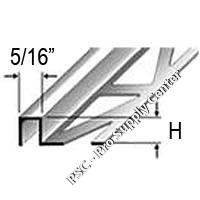

Dural Duraplus Box Section Transition Profiles Aluminum Anodized

Transition Strips

Height: Choose from menu

Material:

Aluminum – available in natural and anodized

Please choose profile height from pull-down menu.

Application:

DURAPLUS profiles by Dural have a visible 8 mm (5/16â€) width surface area and were developed for improved visual joint design. The application is recommended wherever the flooring material must meet a high aesthetic requirement. For example, show rooms or art galleries. DURAPLUS facilitates a clean separation of different flooring materials, or areas. Besides the decorative function, DURAPLUS provides the edges of the floor with the maximum protection from impact damage.

Material:

The following versions of the profiles DURAPLUS are available: aluminum natural, aluminum anodized, Aluminum high gloss anodized, stainless steel natural, stainless steel polished ("Star" with peel-off strip), stainless steel high gloss ("Star" with peel-off strip).

Properties:

DURAPLUS profiles of aluminum are applicable wherever no exceptional chemical reactions are expected. Careful handling of cement materials is required to avoid corrosion. Because aluminum is sensitive to alkaline media's all residues of mortar, tile cement or joint cement have to be immediately removed from all visible surfaces. The profile is to be completely embedded into the contact layer. This avoids cavities to generate where alkaline water might accumulate.

DURAPLUS profiles of anodized aluminum are of special refinement and therefore the surface is usually not subject to changes. The visible surfaces however, must be protected against any cement materials. Damages can generate because of scratching or abrasion.

DUROSOL profiles of stainless steel are especially suitable for areas subjected to high stresses due to chemicals and acids. They meet highest requirements of resistance to mechanical impact. Stainless steel profiles are used in foodstuff industry, swimming pools, in hospitals and breweries. The following is valid for all materials: The applicability with respect to mechanical and chemical resistance is to be determined for each individual case.

Handling:

- Select the DURAPLUS profile according to the thickness of tiles.

- Apply tile cement in the appropriate area using a notched trowel.

- Press the DURAPLUS profile into the cement bed and align.

- Completely cover the fastening legs.

- Leaving a joint of 2 mm between tile and profile. Press the tiles tightly into the cement bed and align them flush with the upper profile edge. Ensure the tiles well embedded into the cement.

- Fill the space between tiles and profile completely with joint grout.

Care and Maintenance:

DURAPLUS profiles do not require any special care. Oxidation layers can be removed with polishing material. A permanent removal however is not possible. The cleaning materials must be free of hydrochloric acid and hydrofluoric acid and must not be abrasive.

Previous Posts

Rubber Insert Replacement for Schluter DILEX-KSN

Dural Durosol Square Edge Profile Aluminum Beige Powder Coated

Inside Corner for Schluter RONDEC-STEP

Schluter DITRA-HEAT-E-RS Non-Programmable Thermostat

End Cap for Schluter DILEX-EHK/-HKS

Schluter DECO Tile Edge Protection / Decorative Profiles

Dural Durosol Square Edge Profile PVC Beige

Inside Corner for Schluter DILEX-AHKA

Dural Duralis Listello Deco Aluminum Profiles 1 Inch

Dural Duralis Listello Deco Brushed Stainless Steel Profiles

Schluter BARA-RTP Balcony Gutter System Edging Profiles

Mark E StringA-Level Wall Tile Installation Bubble Level Case

Mark E Pre-Pitch Shower Sub Floor Slope Pitch Standard Kit

Schluter QUADEC Finishing and Edge Protection Profiles

Connector for Schluter BARA-RTP